I-valve yesango ephezulu yesiqhingi esivamile

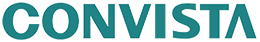

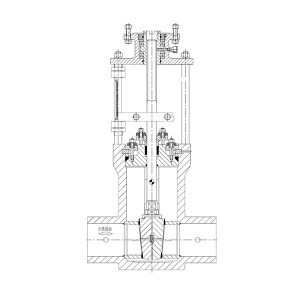

| Thayipha | Isango Valve |

| Imodeli | I-Z962Y-900 |

| Ububanzi bokuqanjwa | DN 150-500 |

Umkhiqizo usetshenziselwa uhlelo lokuphakelwa kwamanzi lwamandla we-AP1000 wamandla enuzi. Ngesikhathi sokusetshenziswa kwayo, i-valve yesango kufanele ivuleke ngokuphelele noma ivalwe ngokuphelele esikhundleni sokusebenza njengokulawulwa kokugeleza nokucindezela.

- Ivelufa isebenzisa isakhiwo self-uphawu futhi zombili iziphetho uxhumano ashiselwe.

- Umshini wokuvala uqukethe uhlobo lwe-wedge-flashboard enesikhungo esiguquguqukayo, phezulu phezulu kanye nebhodi lokubamba phansi. Eqondiswa ngokuqondisa ukudideka emzimbeni we-valve, iqhuba ukunyuka nokwehla.

- Nge-cobalt-based rigid alloy build-up welding, indawo yokufaka uphawu ifaka ukumelana nokushisa okuphezulu, ukumelana nomhuzuko, ukumelana nokugqwala, anti-ukunwaya nokuphila kwensizakalo ende; ukuphakama kokushisela kwe-valve disc nesihlalo ≥3mm.

- Ngokudideka okuqondisayo, umzimba we-valve unikeza ukuholwa okuphelele kokushaywa kwe-flashboard ukuvula nokuvala.

- Ngaphansi kokwelashwa kokulwa nokugqwala kanye ne-nitrogenization, indawo yesiqu se-valve ifaka ukumelana nokugqwala okuhle, ukumelana nomhuzuko nokufakwa uphawu kwebhokisi lokufaka okuthembekile.

- Uhlobo lwe-wedge othomathikhi lwesakhiwo esine-flashboard esinezikhungo eziguquguqukayo sinezici ezilandelayo: isikhungo esiphakeme esiqinisiwe kanye ne-cushion block (ukuxhumana okuyindilinga) kungalungisa i-engeli efanayo phakathi kwe-flashboard kanye nesihlalo se-valve ngokuzenzakalela ukwenza indawo yabo yokubekwa uphawu inamathele ngokuqinile futhi iqinisekise ukubekwa uphawu okuqinile; Kufakwa iqembu lama-gaskets wokulungisa phakathi kwesikhungo esiphezulu ne-flashboard ukuze kulungiswe ububanzi be-flashboard futhi kunxephezele ukuhuzuka ngemuva kokusebenza kwe-flashboard nokulungisa. I-groove e-elastic isethwe phakathi kwama-flashboards angakwesobunxele nangakwesokudla ukuvimbela ukubambeka ngesikhathi sokuvala i-valve. I-flashboard yesakhiwo inokushintshana okuhle nobunzima obukhulu bokwenza, futhi izindleko zayo ezijwayelekile ziphakeme kunezakhiwo ezifanayo ze-flashboard ne-wedge elasticboard.

- I-valve yamukela uhlobo lwesakhiwo sesihlalo se-valve sokushisela. Ukutholwa kwe-Magnetic powder kwenzelwa i-fillet weld ukuqinisekisa ukuthi izinga le-welding elihlangene lihambisana nezidingo ezijwayelekile.

- Ukuxhuma oku-grooved kohlobo lwe-T kwamukelwa isiqu se-valve kanye ne-flashboard ye-othomathikhi ye-doublege-flashboard gate valve enesikhungo esiguquguqukayo. Ibhodi yokubamba isethwe ku-T-type groove ye-flashboard ukukhawula ukuvulwa kwama-flashboards angakwesokunxele nangakwesokudla ngemuva kokuvulwa kwe-valve nokuvimbela ukuwa kwe-flashboard. Inhloko yesiqu se-valve yimbulunga. Ngesikhathi sokuvalwa kwe-valve, amandla agxiliwe asetshenziswa yisiqu se-valve ebhodini lokubambelela ukwenza amandla okuvala abe ngaphezulu ngisho nangesikhathi sokuvalwa kwe-flashboard futhi aqinisekise ngisho nengcindezi yezindawo zokuvala uphawu ze-flashboard nendawo ye-valve nokufakwa uphawu okungcono.

- Njengoba i-pendant collet njengengxenye eyinhloko yokucindezeleka, ingxenye yokuzibamba uphawu yamukela ingxenye eyinkohliso futhi ukuhlangana kwayo kwezicubu kuphakeme kunephaneli. Okwamanje, isebenzisa izinqubo ezihlanganisiwe zokutholwa kwe-ultrasonic nezinqubo zokubona i-magnetic powder ukuqinisekisa ukuthi ingxenye yekhwalithi ehlanganisiwe ihambisana nezidingo ezijwayelekile.